Test System Development

Experts in Test System Development

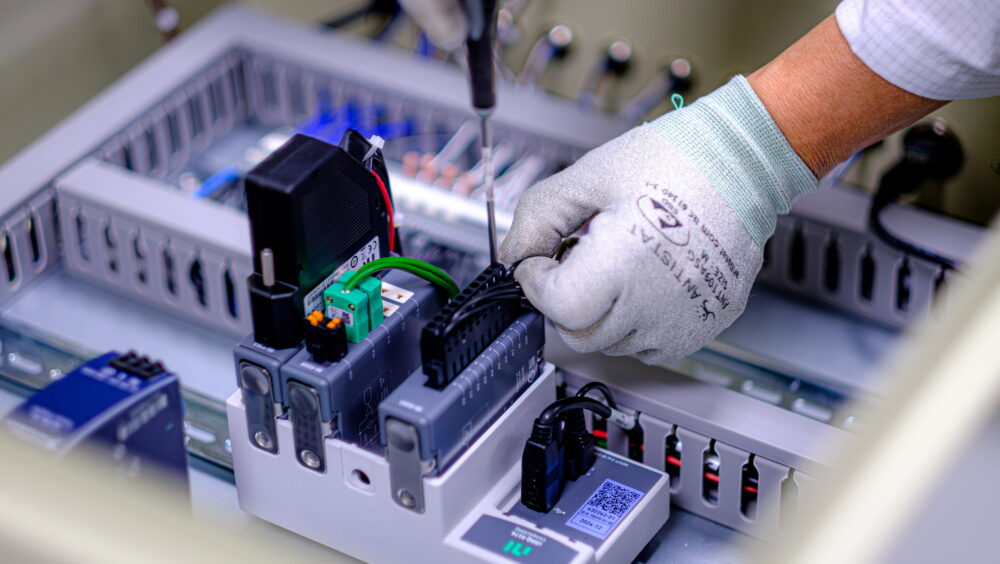

At Novator Solutions, we specialise in the design and development of complete test systems. We offer customised solutions to meet your needs, from crafting optimal testing strategies to developing automated test systems in order to verify and improve your product quality.

What we do

Test Systems for Electronics, Mechanics, Machine Vision

and Beyond

We provide a broad selection of test systems to support companies in a wide variety of industries. Our experience covers everything from electronics and mechanical parts to machine vision and beyond. This includes – but is not limited to – testing motors, electronic equipment, and products requiring sound or vibration analysis.

We support our customers with everything from basic functional testing to more specialised or even customised needs, such as testing rotating machines or monitoring products over time. Our systems help verify electrical properties, assess durability, and automate visual inspections. We also offer solutions for continuous testing during development and for monitoring product performance after launch.

Complete test system for the entire product life cycle

At Novator Solutions, we build test systems tailored to your needs at every stage of your product’s lifecycle.

This end-to-end approach helps you meet industry requirements, while also giving you precisely the data and insights needed to continually improve your products and processes over time.

Efficient development, production, and follow-up

- During development: We help you test new ideas quickly and accurately, helping you bring your products to market with greater speed and assurance.

- During production: Our automated systems ensure every product meets your quality standards and production targets, while detecting issues early to prevent costly setbacks.

- After launch: Our monitoring solutions track real-world product performance, identify trends, and alert you to potential problems before they escalate.

Design and Development

of Complete Test Systems

Novator Solutions offer tailor-made test systems for all stages of product development and production. We help you focus on developing and producing your products with the highest quality standards. With over 150 years of collective experience in designing test systems for the Swedish industry, we possess the expertise to comprehend the intricacies of your complex products and develop test systems based on proven methodologies.

Custom Test System Development

We develop test strategies to optimise product testing and, when necessary, create customised requirement specifications tailored to your unique test system. Subsequently, we craft an automated test system according to your wishes and specifications, conducting verification before delivery, and final verification upon installation, along with handover and training. When developing additional test systems, we recommend using test system frameworks to reuse existing system components. For future maintenance, we offer support contracts tailored to suit your needs.

Automated Test Systems

for Increased Efficiency and Reliability

By weaving advanced automation into your testing processes, Novator Solutions help you achieve faster throughput, greater consistency, and significantly reduce the risk of human error. Every system we build is carefully tailored to your unique requirements, making sure it integrates smoothly with your products and existing workflows.

For your peace of mind, we carry out thorough verification procedures both at our facility and at your site. This means you can trust that your system will provide accurate, reliable results from the very start. This approach guarantees that you receive a complete solution that enhances your testing capabilities, reduces operational costs, and provides the reliable data you need to keep up the highest quality standards.

Scalable and Reusable Test Systems for the Future

Our test systems are designed to scale with your business and adapt easily for use in new projects. This allows you to stay flexible when faced with changing needs or upcoming product releases. By using flexible designs and reliable components, we facilitate system reusability to save you time and money in the long run. This way, your investment stays valuable and relevant as your operational needs evolve.

Test System Development: The Process

We suggest following some or all of the steps outlined below to ensure the successful delivery of your complete test systems. If you prefer, you are welcome to participate in every stage of the process.

Pilot Study: We develop a requirements specification, analyse requirements and estimate the cost of your test system.

Development: We develop and manufacture the system either for you or in collaboration with you, depending on your preference.

Factory Acceptance Test (FAT): The system is verified in our facility before being delivered to you.

Installation: The system is delivered and installed at your location.

Site Acceptance Test (SAT): The system is inspected and verified on-site at your location.

Handover: We train you to take over responsibility for the system.

Support and Service: At request, you have the option to sign a support agreement for service, support, and calibration.

R&D Testing

R&D testing often requires more accuracy and greater scope than production testing, which places higher demands on the hardware and software of the testing platform. The results of R&D testing are provided by analysis that shows trends and changes with traceability. Establishing a reliable and robust foundation for analysis and validation is crucial. This can be attained through easily editable tests, adaptable configurations, and swift hardware replacement options.

Some examples of R&D testing are:

- Prototype testing

- HIL (hardware in the loop) testing

- Validation testing

R&D Test Systems with Novator Solutions

We specialise in developing and delivering complete R&D test systems tailored to your specific requirements. If required, we also offer access to individual consultants with cutting-edge expertise. With extensive experience across various industries, we understand the critical aspects of testing products and components. Drawing from insights gained through our own product development activities in other departments, we possess valuable insights into product development processes and cycles.

Our standardised approach to test system development in LabVIEW yields significant benefits, including enhanced quality and reduced time on the market for both our clients and internal projects. By adopting standardised test platforms across multiple departments, modules developed can easily be reused for production tests. All our consultants adhere to proven architectures and designs, ensuring the delivery of highly reliable systems and promoting higher rates of reuse.

Our Tools

Test Systems with LabVIEW, TestStand and WATS

At Novator Solutions, we build robust test solutions leveraging leading platforms like LabVIEW, TestStand, and WATS. LabVIEW facilitates quick creation of bespoke test applications tailored to your specific requirements. TestStand offers a comprehensive framework to manage and automate even the most complex test sequences with ease.

WATS Test Data Management (TDM), our cloud-based test data management platform, ensures secure, instant access to results, enriched with advanced analytics and streamlined reporting. This powerful combination equips you with scalable, reliable systems and meaningful insights to enhance quality control and operational decisions.

Test System Development: Production

To ensure the quality and functionality of a product, all items—or a sample of randomly selected items—undergo production testing. Various methods are employed to measure different parameters, ranging from voltage, current, pressure, and flows to control signals and fault detection. Specialised equipment such as sensors, probes, and cameras designed for this specific purpose are utilised and automated through software.

Given the increasing complexity of modern products, early fault detection is crucial to minimise repair and maintenance needs. Test systems must therefore be reliable and efficient, aiming to reduce production costs while providing essential data for analysing and evaluating whether a product meets the quality standards and requirements of your customers.

Some examples of production tests are:

- PCB testing

- Functional testing

- Performance testing

- Visual testing

Production Test Systems with Novator Solutions

We develop and deliver complete production test systems according to your specifications. To achieve the highest quality and minimise production costs, Novator Solutions use proven platforms to develop your test system. We use NI TestStand, LabVIEW, and WATS to deliver test systems customised specifically to your requirements and wishes.

By using platforms developed specifically for test systems, we significantly reduce the development cost of test systems and hence your production cost. With the most certified LabVIEW and TestStand architects and developers in the Nordic region, we further minimise development time.

With automatic report management through cloud-based test data management software WATS, we can efficiently and securely deliver statistical and qualitative analysis capabilities for test data, RMA tests, and repair data for your production in real-time through the web browser. When it comes to test fixtures, electrical cabinets, and mechanical engineering, we have partnered with industry-leading specialists to deliver reliable and robust rigs to meet your specific testing needs.

Reduce Production Costs with an Efficient Test System

A well-designed test system can help reduce costs and maximise profitability within your manufacturing process. By automating and fine-tuning test processes, your production reduces downtime, catches issues early, and avoids expensive rework or recalls. High-quality test data gives you the insight needed to fine-tune operations, improve output, and stay aligned with industry standards. At Novator Solutions, we achieve all this while also keeping product quality front and centre.

Test System Development: Control and Monitoring

In product evaluation, monitoring tests are frequently conducted alongside control tests. These monitoring tests are typically more extended, aiming to track various parameters and detect trends effectively. Precision is vital in these assessments, monitoring numerous measurement points to ensure no developments are overlooked throughout the testing process.

A monitoring system needs to have long run times without errors, which often leads to the use of real-time hardware and software to ensure a robust system. Similar to R&D testing, many parameters need to be measured in order to be able to correctly assess products in monitoring tests.

A few examples of control and monitoring systems are:

- Stress and fatigue testing

- Quality testing

- Continuous testing

- Climate testing

Monitoring Test Systems with Novator Solutions

We can help design systems from scratch. Through extensive experience with diverse sensors, collaboration with leading instrument manufacturers, and partnerships with established fixturing and engineering companies, we deliver control and monitoring systems that perfectly meet your requirements. The significant overlap between R&D and production testing allows for extensive test reuse, which reduces the development time for complete control and monitoring systems.

Quality Assurance

Test Systems with Traceability and ISO Compliance

Our test systems are developed with traceability and compliance in mind from the start. They collect and store detailed test records to ensure every product can be traced. We help you stay aligned with ISO standards and regulatory requirements, and provide the documentation needed for audits and reviews. This reinforces regulatory alignment while also helping you drive lasting improvements in your operations.

Test Systems for Different Industries and Applications

The Manufacturing Industry

Our test systems for the manufacturing sector are designed to support high-volume production environments to make sure every component meets stringent quality standards. We offer solutions for functional testing, end-of-line inspection, and process monitoring, tailored to the specific needs of manufacturers across diverse industries.

The Automotive Industry

In the automotive sector, where safety is a top priority, we build test systems for electronic control units, sensors, actuators, and entire assemblies, serving both R&D and production phases. Our solutions facilitate rapid validation, compliance with automotive standards, and efficient fault detection throughout the vehicle lifecycle.

Medical Technology

In medical technology, precision and traceability are non-negotiable. Our tailored test systems are engineered to validate the functionality and safety of devices, from diagnostic instruments to implantable components, while also maintaining adherence to regulatory requirements and robust data management for audit and certification purposes.

Choose the Right Test System for Your Business

The test system you choose will have a real impact on your product quality, company reputation, and financial performance. That’s why we work alongside you to get a proper understanding of your requirements, your strategic objectives, and the operational hurdles you’re dealing with. We help you make sense of the technology landscape, design the right system architecture, and plan the integration in order to extract real value from your investment. If you need a system built from scratch or just want a setup that can grow with your team, we’re here to help.

Test System Development with Novator Solutions

Need a test system that meets your exact specifications? Rely on us for unparalleled expertise and seamless execution from start to finish. Our consultants at Novator Solutions are experts with over 150 years of combined experience in test system development. We work closely with all of our customers and tailor test systems to achieve the best possible solution.